Date: Issue 110 - October 2021

Defence Turkey: Can we start our conversation with a brief introduction of Kale Arge Company, which was established in 2013 as a subsidiary of Turkey's industrial giant Kale Group for research and development activities? To what extent have you achieved your initial goals in the last 8 years?

Cüneyt KENGER: Kale Arge was established in 2013 to carry out research and development activities on Kale Technical Group's areas of interest. In the following years, it started to focus entirely on "gas turbine systems." Kale Arge's main goal is to become a center of excellence for gas turbine systems – therefore, it continues all its work in this direction.

Within the scope of the 'Turbojet Engines Development Project' carried out by Kale Arge under the administration of the SSB, the qualification of the indigenous turbojet engine KTJ-3200, which was developed by Kale Arge entirely with domestic and national capabilities, was completed, including all its control accessories. Currently, acceptance activities have been started under the project.

In line with the strategic vision of the SSB, the project proceeded with the aim of no foreign dependency in any way. Both the turbomachine design and all subsystems of the engine, including the Electronic Control Unit, Control Software, Fuel Control System, Alternator, Igniters, and all the test infrastructure needed to develop a Gas Turbine engine were developed by Kale Arge.

Turkey's first Turbojet Engine, KTJ-3200, will be integrated into SOM, while another variant was developed through additional activities (interface differences, software differences, control/accessory differences) within the scope of the project for ATMACA. A contract was signed for the integration and serial production of KTJ-3200 Turbojet Engine to national missiles.

With the know-how and experience gained from the KTJ-3200, Kale Arge carries out different turbojet engine development projects with its own resources.

When we look at the point we have reached, we can say that we have taken important steps towards becoming a "Center of Excellence for Gas Turbine Systems" and have achieved critical accomplishments. But we still have a lot of work to do.

Defence Turkey: What can you tell us about Kale Arge's current organizational structure, personnel, performance in the last two years, as well as targets and expectations for 2022?

Cüneyt KENGER: Kale Arge carries out its activities at three campuses.

Development and Test Center (KA GTM) is located in Tuzla. The company headquarters is at this campus. Engine testing infrastructures, including engineering and support unit offices, prototype production infrastructure, engine assembly infrastructure, laboratories for control/accessories, and Turkey's first and only Turbojet Engine Altitude Test Facility, are located at this campus. Kale Arge Office in Technopark Istanbul is used as an additional engineering office, and Kale Arge Ankara Branch acts as the communication office.

At Kale Arge, we currently have a team of 110 people. The vast majority of them are young engineers specializing in their field. At the same time, there is a strong consulting network that supports them.

In the last two years, we have made a significant effort to produce the KTJ-3200. We focused on increasing and verifying the reliability, manufacturability, and repeatability of the engine and control/accessories. We are talking about a very difficult and tiring period affected by the pandemic process.

The integration and mass production of the KTJ-3200, as well as the qualification of our new engines, will take place in 2022. We believe that Kale Arge will also grow and expand in this process.

Defence Turkey: What can you tell us about Kale Arge's current production and test infrastructure and annual production capacity?

Cüneyt KENGER: KTJ-3200 Engine Serial Production is carried out entirely with domestic resources and especially with the maximum use of Kale Group's technical capabilities.

Kale Arge acts as an "integrator" in terms of serial production. In other words, we carry out the management of the supply chain, assembly, and testing/evaluation.

Based on the requirements, our current production plan has been determined as 150 engines per year. Our production capacity is well above these numbers.

Production is one of our strongest points. Moreover, our valuable sub-producer companies also support us in their fields of expertise, and we are grateful to them.

“With the experience gained from the tests of the prototype engine in the Altitude Test Facility, the design tools were improved and calibrated for all flight envelopes. Thus, the design of the prototype engine could be improved quickly.”

Defence Turkey: Which capabilities and technologies do you prioritize for Turbojet Engine development and production? What makes you different from other domestic and foreign manufacturers that carry out R&D activities in this field?

Cüneyt KENGER: The KTJ-3200 Turbojet Engine was developed to have a compact design, high thrust/weight ratio, and low fuel consumption in line with the requirements of the platforms it is integrated into.

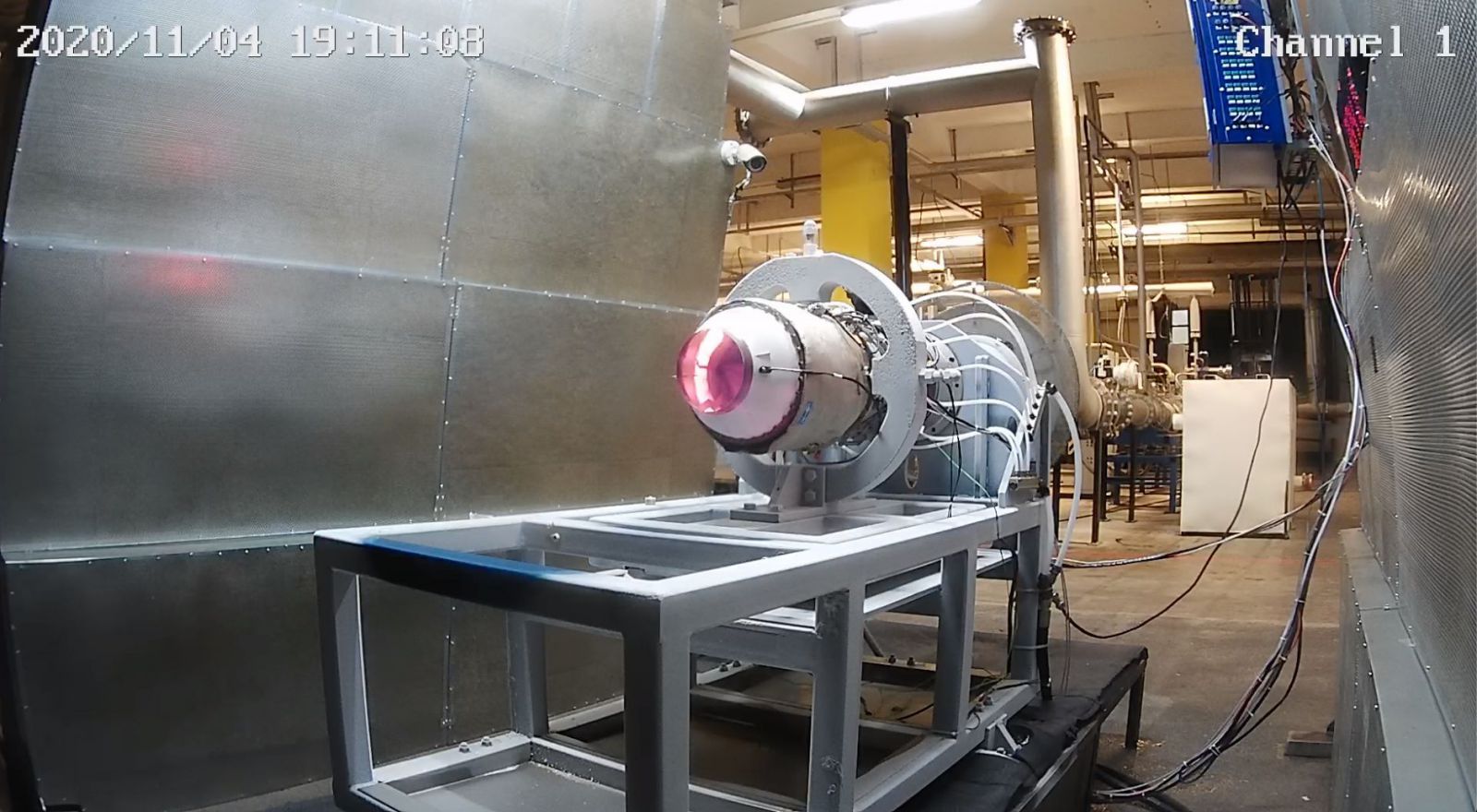

These engines have their own design challenges. In particular, optimized performance outputs suitable for platform requirements at different altitudes and speeds and the ability to be started in the air through windmilling are important issues in terms of design. But even more important is being able to verify them and qualify the engine. Thanks to the Altitude Test Facility of Kale Arge, we were able to identify improvement needs during development tests and qualified the engine. This is one of the most critical points of this task.

Again, using the results of the tests carried out with the Altitude Test Facility, we made our own design tools. We can also create reliable and tested performance codes of our engines.

One of the most critical issues is understanding customer needs and translating them into technical requirements in a healthy way. We work in perfect harmony with our partners SSB, TÜBİTAK-SAGE, and ROKETSAN teams. We carry out our activities with a one-team approach. This is one of the critical points of developing systems optimized for the needs of domestic air platforms.

In addition to innovative approaches, the most critical issue in production technologies for us is that the engine should be reliable, qualified, and can be produced in Turkey. Kale Technical Groups' high level of production capability makes our work much easier.

Defence Turkey: What can you say about the current domestic production rate of the KTJ-3200 Turbojet Engine? Since there is no aerospace-specific, long-lasting, and quality M50 or M50Nil steel or ceramic ball bearing production in Turkey, the bearings for turbojet engines have always been procured from abroad (through bearing companies Cerobear or Timken). Was there any problem in the procurement of sub-systems during the development and prototype production process due to export restrictions?

Cüneyt KENGER:The serial production of the KTJ-3200 engine is carried out entirely with domestic resources and especially with the maximum use of Kale Group's technical capabilities. Bearings, which are the most critical of the components with foreign dependency, were produced indigenously by Kale Aero and some other subcontractors of Kale. We started to produce bearings of different structures and types according to our turbojet engine requirements.

We aim for the maximum level of domesticity in both KTJ-3200 and other engine projects that we carry out with our own resources. This is the main reason for Kale Arge's capabilities in the design/development/production of engine control/accessories. This also is the basis of the bearing issue that we have just mentioned.

Defence Turkey: Considered an important milestone in the development of the Turkish Defense and Aerospace Industry, the 'Development of Turbojet Engines Project' was initiated by the Defense Industry Executive Committee (SSIK) on December 15, 2010. Within the scope of the project, in which TEI and Kale Aero companies competed, US$25 million Research and Development (R&D) contract with a 48-month calendar was signed on February 22, 2012, between Kale Aero and the Presidency of Defense Industries (SSB), with the decision of the SSİK on January 5, 2012. After a difficult process, Kale Arge finally delivered the KTJ-3200 in the first half of 2021, and the integration activities of the engines into the SOM ALCM and ATMACA Anti-Ship Guided Missiles were started. Could you briefly summarize for our readers the development process of the Turbojet Engines Development Project, which began on April 13, 2012?

Cüneyt KENGER: The development process of the KTJ-3200 engine was very challenging.

Unfortunately, in our first years, things did not go as we wanted. We strengthened our team in 2016, and then relatively mature prototype engines started to appear. In 2017, these engines began to be tested intensively. In particular, the altitude performance and launch tests carried out using Kale Arge's Altitude Test Facility lasted for months, and we had to make improvements to the system.

With the experience gained from the tests of the prototype engine in the Altitude Test Facility, we improved the design tools were and calibrated for all flight envelopes. Thus, the design of the prototype engine could be improved quickly.

In 2018, we developed a prototype that works well under certain conditions but cannot show this at every point of the defined flight envelope. So, we implemented additional optimizations and improvements (especially for starting in the air).

In 2019, the engine was able to meet all basic requirements. We increased the number of prototypes then began the qualification tests. By making minor improvements (mostly mechanical), we have taken steps to adapt the engine to domestic air platforms fully. Performance tests based on military standards were officially conducted during this period (such as subsystem tests, environmental tests, and EMI/EMC).

In 2020, we began the qualification rehearsal tests. By the end of 2020, all defined tests had been done internally. Turkey's first turbojet engine official qualification process was initiated. By the middle of 2021, the project was ready for acceptance.

In this whole process, the constructive approach, guidance, and support of the SSB in project management were critical for the success of the project.

“It is quite a significant accomplishment for us to be in contact with the world's leading companies to export a product with a high added value, such as a turbojet engine.”

Defence Turkey: Can you share an up-to-date figure on the total cost of the project? It was previously announced that US$50 million (signed contract value) was spent previously and half of this amount was financed by the SSB and Kale Arge financed the rest.

Cüneyt KENGER: We can say that Kale Group has made a serious investment with its own resources and financed more of the project cost to develop the KTJ-3200 to meet domestic needs and, more importantly, to transform it into a sustainable capability.

Defence Turkey: Can we get information about the sub-system design studies carried out as part of the 'Turbojet Engines Development Project' and the sub-systems developed and produced locally for the engine?

Cüneyt KENGER: The pyrotechnic igniters, electronic control unit, fuel control system, and alternator of the KTJ-3200 were developed by Kale Arge with the intense contributions of our advisers, entirely with domestic resources. We want to take this opportunity to thank our many experts who contributed to these issues.

The fact that the control/accessories of the engine are not foreign dependent is highly critical for procurement continuity of domestic systems and not being subjected to any export license. Moreover, improving our engine control/accessories capabilities also gives us significant advantages in our new engine projects.

Defence Turkey: At the signing ceremony, it was shared that a total of 26 comprehensive tests, 15 of which are sub-system tests and 11 of which are system tests, will be carried out within the scope of the 'Turbojet Engines Development Project.' What can you tell us about the extensive tests carried out under the project during this period when the development phase was completed, and the serial production phase was started?

Cüneyt KENGER: Subsystem level qualifications and environmental tests are critical in bringing such engines into the inventory.

The "Altitude/Speed Start" and "Altitude/Speed Performance" Tests were the most critical tests of the Project that were carried out in the Altitude Test Facility of Kale Arge. There are also special tests for Aerodynamic Performance; indispensable tests for platform integration such as Air Turbulence Tests and Waterproof Tests.

Finally, of course, there are Durability Tests, which verify mechanical reliability. These durability tests are carried out on the ground far beyond the required flight times.

The types and performance criteria of all these tests may differ depending on the platform to be integrated. We have completed these tests for domestic air platforms multiple times.

Defence Turkey: Could you inform us about the collaborations/activities you have carried out with Universities and TÜBİTAK within the scope of the Turbojet Engines Development Project?

Cüneyt KENGER: Within the scope of the KTJ-3200 Project, we conducted intensive collaborations with universities such as ITU, METU, TOBB ETU. These collaborations, which started in the early stages of the project, are currently being continued in new projects of Kale Arge in a multidimensional manner. Our consultancy network is getting stronger and growing day by day. We are actively cooperating with TÜBİTAK-MAM for materials engineering.

TÜBİTAK-SAGE and ROKETSAN both act as the platform providers in our projects and are our most important partners in system engineering and some special tests.

Defence Turkey: What can you say about the installation and commissioning of the Altitude Test Facility and its role in testing processes? The system, which can simulate weather conditions at 5,000m altitude and requires 10MW of power, was established at Kale Arge's Development and Test Center in Tuzla Organized Industrial Zone as part of the Turbojet Engines Development Project. Is there any other test system with similar capability in our country?

Cüneyt KENGER: Our Altitude Test Facility is one of our most important tools for the development of the KTJ-3200 Engine. Located at the Kale Arge Tuzla Development and Test Center campus, it is an engine test system where 0-5km altitudes and speeds up to 0.95M speeds can be simulated. Kale Arge Altitude Test Facility was developed entirely by Kale Arge, established with the help of Kale Technical Group companies, and qualified under the KTJ-3200 Project.

Similar Systems exist abroad, but their use is very costly. Of course, there are also restrictions on accessibility. Our Altitude Test Facility will also be indispensable for the qualification of new engines we are developing with internal resources. As a matter of fact, the engine test rigs we set up in our Development and Test Center, the test/evaluation capability we have acquired, as well as the know-how we have developed are at least as critical as the development of the KTJ-3200.

Defence Turkey: Could you give information about the technical features, dimensions, thrust power (continuous and 'over thrust') and range, alternator structure and power, compressor structure and number, rpm (previously announced as 40,000rpm and 38,000rpm), flight altitude, windmill starting altitude, main parts and service life of Turkey's first national turbojet engine KTJ-3200, which is optimized for use especially for air platforms, target drones, and UAVs?

Cüneyt KENGER: As the name suggests, the KTJ-3200 Turbojet Engine has a thrust of 3,200N (Newton). It has a 4-stage axial compressor, circular combustion chamber, and single-stage turbine. It weighs 50kg and has a compact structure that can be integrated into different missiles. Thanks to its built-in alternator, it can supply power to the platforms it is integrated into.

One of the most important points for the KTJ-3200 is that the performance code developed for the entire operating envelope has been verified by tests, thanks to our Altitude Test Facility. The performance code verified for 0-5km altitudes and up to 0.95M speeds. So, the performance optimization and qualification of the engine were conducted in this envelope. The KTJ-3200 can provide “Overthrust” thrust when needed. You can see some tips on operating RPMs in our test videos. We can provide this as open-source information.

“The integration and mass production of the KTJ-3200, as well as the qualification of our new engines, will take place in 2022. We believe that Kale Arge will also grow and expand in this process.”

Defence Turkey: Could you give information about the number of people (blue-collar workers and R&D engineers) who worked in the KTJ-3200 Turbojet Engine design team and the man/hour data spent on the development process?

Cüneyt KENGER: Unfortunately, it is not possible for us to share this information as they are the private data of Kale Arge. However, we can say that all the experiences and challenges have taught us a lot for turbojet system engineering management, project management and planning. We have very pinpoint data in terms of being able to plan the new projects ahead and manage the risks correctly.

Defence Turkey: What can you tell us about the scope and test and delivery schedule of the 'Turbojet Engine Procurement and Integration Project,' the contract of which was signed with the Main Contractor ROKETSAN in June 2021, and the signing ceremony was held on August 18, 2021, as part of the IDEF '21 Fair? In his statement to Anadolu News Agency, Kale Group Vice Chairman of the Board and President of Technical Division Osman OKYAY said that 13 engines will be delivered by the end of 2021. Are these new production engines coming out of the serial production line or manufactured during the development phase?

Cüneyt KENGER: As you know, serial production projects include LRIP (Low-Rate Initial Production) phases. 2021 deliveries can be considered in this way. These tests will be an important milestone in the integration studies that have been carried out to a large extent. Line qualification activities for serial production are also carried out in parallel. The deliveries of the serial production engines will start in 2022.

Defence Turkey: Osman OKYAY also noted that there would be a bigger and a smaller model of the KTJ-3200. He stated that the bigger engine would have 20% higher thrust than the KTJ-3200, while the smaller engine will have about 50% thrust of the KTJ-3200. What can you tell us about the technical specifications and project schedules of these engines? In response to a question, I asked at the press conference held before the IDEF '21 Fair, ROKETSAN General Manager Murat İKİNCİ explained that the small engine developed for Roketsan is one of the two candidates (competing with TEI-TJ300 Engine) to power the Medium Range Anti-Ship Guided Missile developed for the Turkish Naval Forces Command. Can you share information about which project the bigger engine is being developed for?

Cüneyt KENGER: There are 2 main projects we are working on internally:

A small turbojet engine developed for light air platforms/missiles, and a new engine for different conditions with similar dimensions to KTJ-3200 but with a revamped aerodynamic design. It has higher thrust and lower specific fuel consumption. These engines were designed according to the requirements of both domestic and international customers. We cannot share details about the platform types. We are producing prototypes of these engines. Performance tests will begin soon. We will keep you informed of developments.

“It is quite a significant accomplishment for us to be in contact with the world's leading companies to export a product with a high added value, such as a turbojet engine.””

Defence Turkey: During the signing ceremony of the 'Turbojet Engines Development Project,' it was pointed out that the national turbojet engine could also be used as Auxiliary Power Unit (APU) in different helicopters with minor modifications. Considering the fact that the KTJ-3200 is a qualified turbojet engine in serial production, do you have a roadmap for APU derivatives for use on aircraft (like HÜRJET and MMU/TF-X) or helicopters?

Cüneyt KENGER: We do not currently have a study on APUs.

Defence Turkey: What can you tell us about Kale Arge's export activities and targets?

Cüneyt KENGER: There are information requests from abroad regarding the KTJ-3200. However, our top priority is to meet the needs of domestic air platforms. There are also foreign customers interested in the engines that we are developing with our internal resources. In fact, the design requirements for these engines have basically come from these foreign customers.

The fact that our engines are not subject to export licenses of other countries and that performance maps/codes can be verified in our Altitude Test Facility make Kale Arge very attractive for foreign companies. We cannot disclose the commercial information, but we can say that this class of engines can be exported. It is quite a significant accomplishment for us to be in contact with the world's leading companies to export a product with a high added value, such as a turbojet engine.

Defence Turkey: Mr. Cüneyt, is there anything you would like to add as a final message to our readers?

Cüneyt KENGER: The design, development, and qualification of aviation engines are complicated and demanding processes. I have worked on the development of Aircraft Engines for 25 years. I spent ten years as an engineer and manager in the world's leading aircraft engine companies. Developing an aviation engine is not just about making a working engine. It is even more important to be able to overcome the problems that arise in the life cycle. This capability is what makes these few companies global Aircraft Engine manufacturers.