Tarih: Issue 70 - September 2016

On July 12, 2016, the capital city of England, London witnessed a historical moment at the Farnborough Air Show, ten years after the launch of the Hürkuş development program. At this important milestone in Turkey’s aircraft development story, that goes back to ninety-years, “Hürkuş” was qualified to receive the international certificate of airworthiness.

After 10 years of a tough development program and challenging tests, hundreds of determined engineers, technicians, pilots, executives, bureaucrats and decision makers, and even a nation gathered to achieve what was once qualified as impossible, preparing to watch once more the maiden flight conducted proudly by Vecihi Hürkuş the “Vecihi VI” manufactured again by Vecihi Hürkuş on 28 January 1925 and to relive the excitement and joy. Receiving the International Type Certificate, “Hürkuş” carried the 90-year-old incomplete aviation story of a country into the future while also shaping the future of the Turkish Aerospace Industry.

During the period following the preliminary and critical design, roll-out and surely the maiden flight; “Hürkuş” went through the system functional tests, air data system calibration, stability and control tests, structural load tests, landing gear emergency procedure tests, low speed flight tests, stall and aerodynamic configuration tests, spin tests, performance tests, aerobatic and operation tests, high speed and air start engine tests and flutter check tests throughout this decade long marathon. To date flying prototypes have performed 571 flight-hours in 535 sorties. During these flights; 35.500 ft. altitude, 356-knot speed and 7 g maneuvres have been tested.

Mr. Özcan Ertem, the Integrated Aircraft Group Head of TAI, one of the closest witnesses of this story enabling this reality’s transformation into a miracle and we met him at Hürkuş’ nest to discuss this process in detail and once again heard the story from him. What have they been through in this ten-year long process? Which stages were reached? How is the mass production process proceeding? Are there any new configurations on the way? When will the Armed “Hürkuş” be airborne? We enquired Mr. Özcan Ertem all these questions wondered by all and received crucial reply. But beforehand we will dive deeply into this story holding a light to a dream of a nation and examine the history chronologically.

The New Generation Basic Trainer “Hürkuş” Development Program was launched in March 2006 upon the contract signed between the Undersecretariat for Defense Industries and TAI. Production of a total of four prototype aircrafts composed of two aircrafts to be used in flight tests and two aircrafts for the structural tests were planned within the scope of the project. As part of the prototype development, production and test activities; the first prototype to be produced was supposed to be the 1st flying prototype, the 2nd prototype would be static aircraft which would tolerate the structural loads, 3rd prototype would be the number 2 flying aircraft and fatigue and damage tests would be performed on the aircraft which would be the 4th prototype.

Following the contract signed in 2006, the preliminary design of the aircraft was completed within the 2007 – 2008 timeframe and the critical design review was accomplished in the first quarter of 2009. Upon the completion of the assembly of the aircraft, the “roll-out ceremony” was realized with the participation of the former Prime Minister Mr. Recep Tayyip Erdoğan, on 27th June 2012 and “Hürkuş” made its debut. Prior to its maiden flight, static robustness, cabin pressure and vibration tests were performed on the aircraft for over a year.

During the tests performed with the special testing equipment at TAI hangars, the number 2 static aircraft, without any systems equipped, was suspended over the hydraulic systems and stress and load tests were performed. In these tests, the required inputs were recorded through approximately 1800 sensors placed over the aircraft. Meanwhile, the canopies of the aircraft were closed and the expansion tests within the airframe were completed during this process. A load that is seven times heavier than the aircraft was loaded onto this static aircraft and the limits of the aircraft were tested by implementing a stress of 7G. These static loads were executed as planned under 21 different load conditions and the number 2 prototype accomplished its test task. As the structural load tests of the static aircraft continued, the first flying prototype was being prepared for its maiden flight. On 31 July 2013, the first flying prototype with the serial number TC-VCH 001 was qualified with the registration certificate by the Directorate General of Civil Aviation. Following this approval, taxi tests of maiden flight “Hürkuş” prototype commenced to be performed on the ground.

Receiving its first registration from the General Directorate of Civil Aviation, the first flying prototype with tail number TC-VCH-001 went through taxi on the runway, wheel steering, right-left drafts, braking lags and acceleration tests both in windy and still weather. Following the control of such phases and confirmation of the European Aviation Safety Agency (EASA) and DGCA, “Hürkuş” was given permission for the maiden flight. After the determination of appropriate weather conditions, altitude and speed limits, “Hürkuş” accomplished its maiden flight with the test pilot Murat Özpala on 29th August 2013

Following the engine start at 07:30 am, “Hürkuş” took off at 07:35 am after taking the required permission from the control tower. During the flight, “Hürkuş” climbed 9500 ft. and completed with the control of flight surfaces and successfully landed after a 33-minute test flight. “Hürkuş” achieved extension of landing gears as planned in-flight and made a successful landing.

Within just over a year, on 10 September 2014, the 2nd flying prototype with the tail number TC-VCI-002 joined Hürkuş family which was conducting its flights with the prototype with tail number TC-VCH-001. Continuing its test flights with TAI’s skillful test pilots Murat Özpala and Murat Keleş, the second prototype already completed many critical tests by October 2014.

As of the beginning of October, the first prototype TC-VCH-001 performed 105 flight-hours in 96 sorties. These flights were tested and recorded at an altitude of 15.000 ft. with a velocity of 295 knots. In 96 sorties performed so far, tests related to the flight system over the aircraft, communication and air navigation tests, stability and control checks, air data system calibration checks and high-lows speed tests were executed.

On the other hand, the TC-VCI-002 just accomplished its sixth flight by the beginning of October. Flight tests were speed up in this period with 2 flying prototypes. Completion of around 500 sorties was aimed throughout the period, which lasted for three years following the maiden flight until the receipt of the international type certificate. However the number of sorties would exceed this number by the completion of the program. By the end of 2014, the focus was moved onto the flight performance and maneuver tests with the 2nd prototype.

.jpg)

A critical threshold was ready to be accomplished for the static test aircraft, which was subjected to maximum load tolerance tests in a special test rig designed by TAI at the TAI facilities, having lasted for 1.5 years starting from the second half of year 2013. The maximum load determined as a requirement for certification was successfully performed over the aircraft under the surveillance of the Directorate General of Civil Aviation and all related certification requirements were fulfilled.

Meanwhile, the test flights continued to be performed by the flying prototypes. As of June 2015, a total of 200 sorties were accomplished by 2 prototypes. The critical phase for the “Hürkuş” which continued its test flights uninterruptedly, with 2 prototypes throughout the remainder of the year, would be starting in January 2016.

“Spin Test Successfully Performed on 20 January 2016”

The first of the abnormal flight conditions known as spin that is a very important and critical stage at the flight-test process and safe recovery tests were performed at TAI facilities on 20 January 2016. The spin tests, a challenging process during which the aircraft was deliberately removed from the normal flight conditions by the test pilot and put into abnormal flight conditions and in which the techniques for safe recovery were identified, were performed. All types of abnormal conditions were tested throughout these tests. Within the scope of the compulsory measures to be adopted during these tests with high risks, a “spin rescue parachute” was mounted on the tail of the aircraft in order to secure the “Hürkuş” and the test pilots. TC-VCI closely followed and witnessed the dangerous dance of the number one Hürkuş TC-VCH from the air.

The critical high-speed test was passed after the accomplishment of the spin test at the end of February. “Hürkuş”, set a record high speed of 659 kilometers per hour on Feb. 28 in a test flight in Ankara. The two-seat “Hürkuş” began a dive from 27,000 feet (9,000 meters) at the test site, reaching a top speed of 659 km per hour during the dive.

“22 March 2016 - Approaching the end of the process to gain Type Certification (TC)”

“Hürkuş” leaving the spin and speed tests behind, tests which are regarded as the most critical procedures of the program, approached one step closer to the certification. The Turkish New Generation Trainer Aircraft “Hürkuş-A” accomplished EASA Flight Test on 22nd-25th of March at the TAI facilities. A European Aviation Safety Agency (EASA) flight-test pilot and a flight test engineer completed a total of six sorties for certification compliance with the “Hürkuş” prototypes HUR01 and HUR02. Tests consisted of the verification of the general flight and handling characteristics of the aircraft’s stability and control, of its stall; spin; maneuvers and aerobatic capability, its navigation and night flying capability, the man-machine interface, the emergency procedures and the overall system characteristics. The EASA’s test flight pilot and engineer found the aircraft compatible for certification.

The air-start tests composed of stopping and starting the engine in the air, which is one of the most critical tests performed over the aircraft, were accomplished on 3 June 2016. The toughest altitude and speed conditions were selected and the air-start performance of the aircraft after its stopping for any reason was tested during these flights; Hürkuş’ engine was stopped 13 times during the tests and following the gliding and stall performance tests with the stopped engine Hürkuş was successfully restarted, passing yet another critical threshold.

The “Hürkuş Certification Closure Workshop” during which the technical issues were discussed and evaluated in Cologne, Germany on 8-9 June 2016, was accomplished with the participation of senior executives and technical experts of the Directorate General of Civil Aviation (DGCA) and the European Aviation Safety Agency and TAI representative

Technical issues were discussed in panels on the first day of the event. Within the scope of the assessment made on the second day of the event, with the participation of Deputy General Manager of DGCA Mr. Haydar Yalçın, EASA Certification Director Trevor Woods and related experts, it was stated that another critical stage for the issuance of “Hürkuş” Type Certification was successfully completed and if the remaining activities could be accomplished the Type Certification might be issued on 11 July 2016.

The Design Organization Approval audit realized by the DGCA and EASA on 15-16 June 2016 as part of the Project was completely and successfully accomplished. Upon the completion of the DOA audit, which is another prerequisite for TC, it was announced by the EASA DOA Team Leader that there remained no obstacles for the issuance of the Type Certification.

With the completion of the DOA audit, another step was taken towards the much anticipated culmination of years of diligence. The month July would be both the ending to the ten-year long story and the beginning of a new era. The EASA (European Aviation Safety Agency) and Turkish DGCA (Directorate General of Civil Aviation) Design Organization Approval (DOA) holder TAI-Turkish was awarded on July 11th 2016 by DGCA with the “TT32 Aircraft Type Certificate” for its New Generation Basic Trainer Aircraft “Hürkuş”, which was also validated on the same day by the EASA with “EASA Validation Type Certificate”.

Under a thorough design, testing, documentation and verification process, following Turkish DGCA Type Certificate, TAI received the EASA Validation Type Certificate at the Farnborough Air show during a ceremony hosted by TAI Chairman of the Board of Directors Mr. Nejat Bilgin and General Manager Mr. Muharrem Dörtkaşlı. The certificate was handed over by Certification Director of the EASA, Mr. Trevor Woods, who is responsible for the certification; organization approvals and rulemaking for all EU designed aircraft, engines and equipment. The ceremony was honored and witnessed by Deputy MoD Mr. Şuay Alpay, Undersecretary for Defense Industries (SSM) Prof. İsmail Demir and distinguished guests.

The development process was accomplished with the aforementioned steps given in chronological order. A new era starts for the Turkish Aviation/Aerospace with this Certificate. The path for the sale of an indigenously designed and produced Turkish Trainer Aircraft to Europe and to the world has been cleared. We may easily surmise that the day does not seem too far away when we can expect to see the “Hürkuş” New Generation Basic Trainer entering into the inventory of the Turkish Air Forces and allied forces.

What awaits us after this point? TAI Integrated Aircraft Group Head Mr. Özcan Ertem evaluated the EASA process and shared details with us in the following interview:

.jpg)

Defence Turkey: You successfully accomplished the EASA certification flight on 22 -25 March 2016.

EASA flight panel experts want to observe the most critical flight conditions of the aircraft by flying the aircraft by themselves. The organization inquires whether the aircraft is actually in accordance with what you have written in the compliance documents and aircraft manuals. EASA pilot and test engineer were present during the certification flight test campaign. They flew the aircraft and said, “yes, the aircraft is in line with the certification requirements”.

Defence Turkey: The static aircraft manufactured for the structural load tests are successfully completed its mission within the program schedule. We presume that the fatigue tests are still being performed on the fourth prototype specially built for the fatigue tests. Could you please share the status of fatigue tests and the process you have passed?

The 4th prototype, which is our second structural test aircraft, is being used for the fatigue tests. We may define the purpose of the fatigue tests as such; during operation, an aircraft is subjected to various external factors during an hour-long flight. It performs maneuvers, withstands several g-loads, performs take off and landings etc. During these flight phases, the aircraft is exposed to various g-loads. During the fatigue tests; we simulate this 1 hour-long flight in 15 minutes within the test setup. Throughout this 15 minutes session, test aircraft is subjected to every loading condition that real aircraft will experience during 1 hour of flight. Therefore, if you extend this fatigue test session to 1 hour, then this will be equal to 4 hours of an actual flight time. The certification requirements dictate us to age the representative full scale test specimen before the flying aircraft and make sure that there are no cracks or failures as a result of aging. If any damage is detected during these tests, we have to re-design or apply a proper repair solution on this aircraft. Afterwards, we have to show that it works and this repair solution will be implemented in the Maintenance Manual so that the customer will be informed. With the successful completion of fatigue test campaign, we will prove over 10 thousand hours design life of the aircraft.

Defence Turkey: How many hours of flight have been accomplished so far during the fatigue tests?

Our fatigue test aircraft is already tested equivalent to 5 thousand flight hours.

Defence Turkey: How many hours of flight is guaranteed by the contract?

Our contract stipulates over 10 thousand hours of flight.

Defence Turkey: So was there specific fatigue test duration for the Type Certification?

EASA required that before the type certification is granted, it had to be shown that no damages would occur on the fatigue test aircraft up to 30% of the estimated lifecycle. As we completed 3,000 hours of testing, we reported the results stating that we have not found any damages on the tested specimen and passed that phase. Before the type certification, prototype number 2 – the static test aircraft passed the most critical 21 load cases, including 7-g maneuver loading. Our estimations are proven, so we completed the static test campaign successfully as well. In total, we prepared a total of 545 certification reports to the EASA for the Type Certification. After the completion of test campaign, full-scale static test aircraft is painted to be used for promotional activities during the fairs.

Defence Turkey: Then the development process of the Hürkuş-A is accomplished from your perspective. Will the flying prototypes continue to be used for the development of Hürkuş-B and Hürkuş-C aircrafts in the following process?

Yes, they will be used. The flying prototypes used within the scope of the Hürkuş-A development program were ordered by the Undersecretariat for Defense Industries. Therefore, as the program ends, these aircrafts will have to be delivered to the government. In other words, although they will not be used in service, as the owner of the order, the government will need to get them back. Our negotiations on this issue are ongoing. And it seems that we will be reaching at an understanding at the end. Although we are selling the aircrafts to our government, the government seems to be granting them for the purpose of their utilization in development program or for performing other tests on them, as they will not be operating them.

Defence Turkey: Will the flights and ground tests of the prototype aircraft continue after the Type Certification?

We aim to use one of the prototypes in launch tests after integrating external stores, prior to the IDEF 2017 event. The government does not yet have an order or a clear decision for the Hürkuş-C configuration. We wish to demonstrate the capabilities of the aircraft with the external stores integration and launch tests. One of these two prototypes will have such a task.

Presently we are performing a post-TC test on the number 2 flying prototype. We are executing the Air Load Calibration Test. This test is conducted for calibration of sensors prior to flight load measurement testing. It is the only way to measure the air load in-flight. Held with hydraulic pistons and equipped with the added loads, the aircraft’s wing spars are flexed, carrying these bending loads. When we were preparing this aircraft for flight, we installed approximately 110 sensors on the aircraft for measuring the stress. We have not used these sensors during the flight tests until today. Now we are performing this test in order to calibrate these devices. With this ground test setup, we will check the signals given by the sensors, for instance, when a ton is loaded. Then we will analyze the signals when the applied load is increased to 2 tons. In this way, we will be reading which signals are given under which loading conditions in the controlled environment on ground. Then we will remove all these extra parts installed over the aircraft and it will be able to fly again.

Since you are capable of reading the data from the sensors in flight, you check the data you read and according to that, you state that, for instance, a 5-ton load is applied on the aircraft during flight. Therefore, in order to measure the actual loads in flight, you need to calibrate the devices on the setup on ground. This is the actual purpose of the air load calibration test we currently execute on the number 2 flying prototype with the fuel, hydraulics, power, seats, etc. all the equipment are being on the aircraft. Since this test was not a high priority for type certification, we deliberately postponed this test to post-TC. During these tests, we will have the chance to see if real flight loads are in line with our design estimations. According to our estimations, the loads we calculated will be slightly over the ones we will see during the flight test, in other words if the aircraft will be exposed to lower loads than expected, this may be regarded as an advantage to increase the lifecycle of the aircraft.

Defence Turkey: Do both flying prototypes have the sensors installed over the aircrafts?

Our number 1 prototype does not have these measurement devices. We decide on which prototype we will perform this test beforehand. Since the number 2 prototype is already manufactured with those measurement devices, these tests are being conducted on it in order to calibrate the devices. There is no need and therefore, our serial production aircraft will not have air load calibration and flight load survey sensors.

Defence Turkey: When are the sensors equipped?

They are equipped while building the wing. You build it and then you switch it off and it remains dead until the test. During the test, you reanimate it and measure it. We will activate to measure it in flight later on.

Defence Turkey: When will the number 2 flying prototype commence its flights again?

It will be ready to fly again by the end of November or at the beginning of December. We will proceed to conduct our test flights with the number 1 prototype until then. When this test is over, we will land the number 1 flying prototype for external store modification. We want to keep one flying prototype for flights or demonstrations. Around February 2017 you may be able to see the number 1 prototype in another form.

Defence Turkey: When do you plan to execute the Armed Firing Test?

We are conducting our preparations to have it completed by April 2017 before the IDEF fair. We aim to install a camera and weapon system to the aircraft and then conduct the launch test.

Defence Turkey: How is the mass production process of Hürkuş-B proceeding?

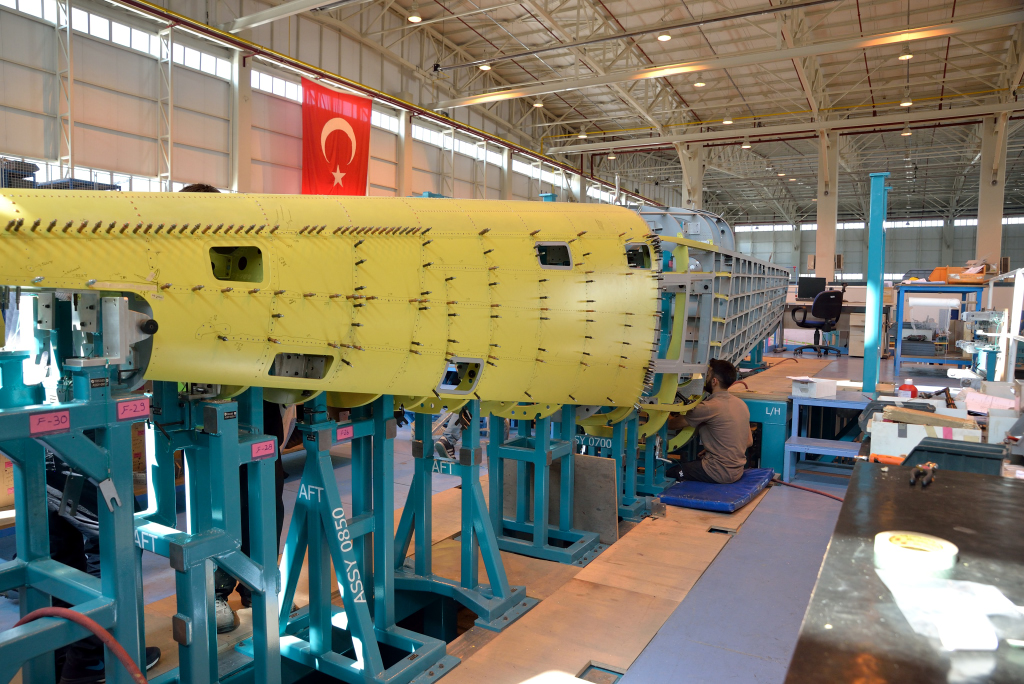

We launched the serial production of Hürkuş-B aircrafts. Two aircrafts are already in the manufacturing line and third one is planned for very soon. We built a line capable of simultaneously manufacturing three aircrafts. We have already ordered all the systems of the aircrafts. We are conducting our preparations as if we are going to deliver the first aircraft in June 2018 as per the program schedule. Aselsan has to deliver us the related system, especially the computer with the software so that we could operate the systems on the ground in the second half of 2017 and get them ready. We are expecting Aselsan to deliver all systems approximately within a year. If everything is on track we need to be accomplishing the maiden flight by the end of 2017. The first delivery will be completed in June 2018 and the final delivery will be accomplished a year later, in June 2019. We will be delivering 15 aircrafts within 12 months.

Defence Turkey: You mentioned that you will be placing the 3rd aircraft to the tool on the mass production line. Could you please elaborate the activities being conducted at the mass production line?

Currently, mass production of three aircrafts is underway. Our mass production continues with 3-fuselage coji , 3-wing coji and with the mate coji to assemble all of them. Later on we will integrate the wings and tail of the aircraft and start our tests. We are conducting detail parts manufacturing either within TAI or at the suppliers facilities. Avionics are installed in mate coji while the landing gears are placed during the final assembly phase. We have another system in these aircrafts through which we monitor the lifetime of each aircraft and place sensors in every aircraft. Periodically, we read the data after the flights and check if the aircraft is exposed to the amount of fatigue equal to our estimations or inquire if it is capable of pulling the envisaged amount of G force? According to the outputs of these inquiries, the lifetime of the aircraft needs to either be extended or shortened. So, for monitoring each aircrafts’ fatigue levels, we place light measurement devices to the aircrafts. Therefore, we launch the life cycle program of the aircrafts in a way.

Hürkuş- B Assembly Line - Wing Coji

Defence Turkey: What is the capacity of the assembly line?

We are capable of keeping maximum 5 aircrafts at the assembly line. Then again, when these 5 aircrafts are on the ground, at least 5 other aircrafts are going under the production phase. 5 aircrafts with wings installed and 5 aircrafts under the interim phase are able to remain at hangar at concurrently.

Defence Turkey: Will the” Hürkuş-B” configuration be structurally different than the “Hürkuş-A” development aircraft?

We do not plan a change. It cannot be discovered which one is the A configuration and which is B configuration without seeing their cockpit.

Defence Turkey: In which systems and sub-systems an indigenization occurred between Hürkuş-A and Hürkuş-B configurations? Could you give us a local content rate?

It is quite difficult to mention a percentage. All structural parts and components of the aircraft are indigenized. Moreover, the avionic systems of the B configuration are becoming indigenous. As from the Hürkuş-A configuration; the lighting and the electrical power distribution systems have already been indigenized. Additionaly, in Hürkuş B we can claim that major avionics of the cockpit are indigenous. The Undersecretariat for Defense Industries initiated the indigenization process of the aircraft’s landing gear as well. Four of our companies are quite eager for this tender, and upon our Undersecretariat’s selection of a company, the indigenization process will be initiated. We submitted the technical specification to our Undersecretariat. The Undersecretariat for Defense Industries will go out to tender. Alp Havacılık, Yepsan, Altınay and Hema companies will be competing in this tender.

Defence Turkey: Will this catch up with the first 15-lot package?

It cannot catch up with the 15-lot mass production package. But, if the target is the 16th aircraft then we may speak of the process following the 16th aircraft. Then again, a contract should be signed by the Undersecretariat for Defense Industries and the program schedule has to start running.

Defence Turkey: There are no official resolutions adopted by the government for the Armed Configuration of “Hürkuş- C”. There are no orders yet. What are your activities regarding this configuration? Which types of options are being planned?

We have not received any order for the “Hürkuş-C” configuration yet. But we still continue our activities. We consider a cockpit in the B configuration that has a trigger mechanism, etc. There is a virtual firing system in the B configuration; you conduct the firing as if you are doing it on the computer. We wish to merely fill the bottom of the wing in the C configuration. We need to examine this issue in detail with our Forces declaring their requirements for the C configuration. They need to define us what they demand and what weapon systems they require. At the end, we have a 1.5-ton payload capacity in this configuration. It is also possible to reinforce it with external fuel tank in order to remain longer in the air. Or you may minimize the endurance and install more weapons. Here we have another capability, which we lack in our other fighter aircrafts. We can claim that Hürkuş’ endurance is for 4 hours.

Defence Turkey: So, are there any activities on the horizon for Hürkuş-D?

I reserved the letter ‘D’ for the maritime. It remains on the table as a suggestion. A guided weaponry system may be integrated to the aircraft. Radars, camera systems, data link could be equipped. Where could our Naval Forces utilize an aircraft with 1.5 tons of payload capacity? We need to discuss this in detail. If we limit it only with the Turkish territorial waters, then a fine study comes up. When we place an aircraft such as “Hürkuş” to our airfields at the coasts, we will be capable of reaching to all borders of our territorial waters in 15 – 20 minutes distance. Therefore, “It could be one of the fastest emergency responses when required”. We need to gather and discuss this. We already shared our ideas about it.

Defence Turkey: We hope that the significant success achieved with the Hürkuş-A development program will continue increasingly and with the same determination and synergy during the ongoing stages of the program. Thank you very much for your time.